Aluminium Alloy in Additive Manufacturing Market Insights

The Global Aluminium Alloy in Additive Manufacturing Market was valued at USD 61.8 million in 2021 and is expected to rise with a CAGR of 24.0% from 2022- 2028 during the forecast period. The expanding aerospace industry and rising utilization of aluminium alloy in additive manufacturing are driving the market. Over the period, there is an advancement in the field of architecture and engineering that has bought many revolutionary changes specifically in the form of digital up-gradation.

Additive manufacturing is known as 3D printing, it is a revolutionary approach to industrial production that enables the production of stronger, lighter, and complex machinery components. The technology can be viewed as a transformation of analog to digital processes.

Digital efficiency and flexibility have bought creativity to the manufacturers that have helped them to understand the key requirement of consumers. For instance, recently OEMs like Airbus have used 3D printing technology to print spare parts of an old aircraft of US Airlines which was anticipated to be a fleet of Airbus A320 with a current engine (A320ceo). The successful, execution of the project has garnered confidence among the manufacturers to further use additive technology for further industrial use. Thus, a rise in global demand for the requirement of less expensive, more durable, stabilized, corrosion resistance products is driving the demand for aluminium alloys in additive manufacturing.

The aerospace industry is one of the growing industries owing to the higher employment and increased revenues it experiences. With the advent of autonomy, there has been an increased demand for autonomous flight systems which has impacted the industry positively.

The 3D Printing Industry is focused on innovating and developing new products that contribute to the net-zero carbon emission goals, during the next several years will propel the industry growth manifold. Therefore, high-strength Al alloys are widely used for manufacturing structural components in the aerospace industry because of their excellent strength-to-weight and stiffness-to-weight ratios as well as good machinability.

Additive manufacturing in the industry caters to its advancement in end-use parts manufacturing and prototyping. Thus, additive manufacturing or 3D printing processes are considered as most suitable manufacturing methods in the industry.

Covid Impact on Global Aluminium Alloy in Additive Manufacturing Market

The additive manufacturing industry has gained popularity during COVID-19 by making urgent parts with rapid designs. However, challenges such as standardization & regulation across this sector could diminish some of the safety concerns identified. For instance, the British Standards Institution (BSI), the national standards body in the UK, released a guide specifically for organizations, schools, and universities manufacturing PPE with no prior experience to support these initiatives. The effects of the global coronavirus pandemic have resonated through many lives, overturning aspects of health care, transportation, and the global economy.

COVID-19 has critically impacted the demand for aluminium alloys in additive manufacturing among numerous end-use industries, namely aerospace & defense, healthcare, automotive, and others. The disruption of supply chain due to global lockdown resulted in delays of raw materials. Thus, disrupted financial flows, along with the growing unavailability of workers have compelled aircraft and automobile manufacturers to operate at minimal capacities. Furthermore, the economical destruction caused by the covid-19 pandemic is majorly driven by a fall in consumption/demand globally.

Scope Of Global Aluminium Alloy in Additive Manufacturing Market Report

Aluminium Alloy in Additive Manufacturing Market is segmented by type, Manufacturing Method, End-Users ,and Region. by type the market is segmented into AL2XXX, AL5XXX, AL6XXX , AL7XXX, and Others. By Manufacturing Method, the market is segmented into Powder Bed Fusion , Directed Energy Deposition, Binder Jetting , and Others. by End-Users the market is segmented into Aerospace, Automotive, AM Services , Health Care, and Others. The report also covers the market size and forecasts for the Global Aluminium Alloy in Additive Manufacturing Market in 26 countries across major regions.

| Report Attributes | Report Details |

| Study Timeline | 2016-2028 |

| Market Size in 2028 | USD 277.6 Million |

| CAGR (2022-2028) | 24.0% |

| By Type | AL2XXX, AL5XXX, AL6XXX, AL7XXX, Others |

| By Manufacturing Method | Powder Bed Fusion, Directed Energy Deposition, Binder Jetting, Others |

| By End-Users | Aerospace, Automotive, AM Services, Health Care, Others |

| By geography | North America: U.S., Canada, Mexico

Europe: Germany, France, U.K., Russia, Italy, Spain, BENELUX, Rest of Europe Asia Pacific: China, Japan, India, South Korea, Australia, ASEAN, Rest of Asia Pacific Latin America: Brazil, Argentina, Chile, Rest of Latin America The Middle East and Africa: GCC, Turkey, Israel, Rest of MEA |

Global Aluminium Alloy in Additive Manufacturing Market Segmentation

Market Research Community provides extensive analysis of the size, share , major trends in each sub-segment of the Global Aluminium Alloy in Additive Manufacturing Market, along with forecasts at the global, regional and country level from 2022-2028.

The AL7XXX alloy type holds the major share in Global Aluminium Alloy in Additive Manufacturing Market

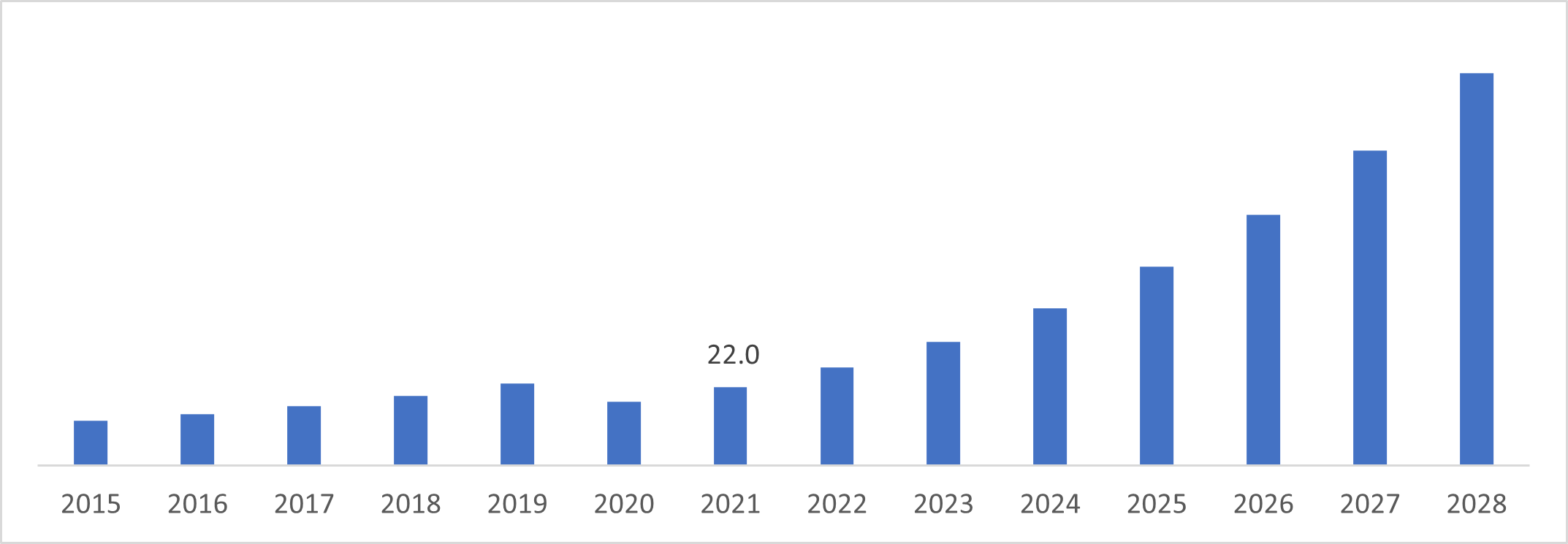

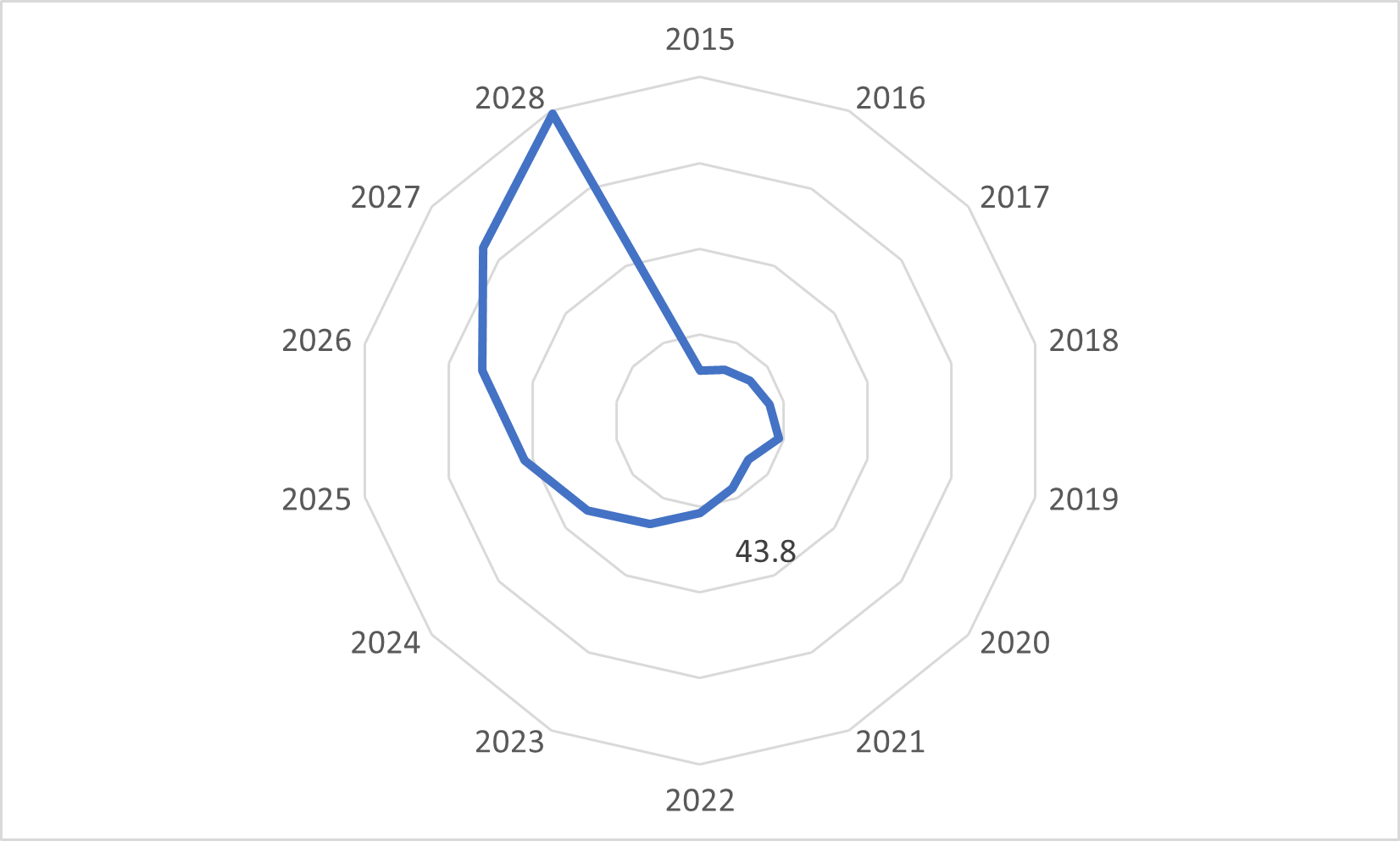

The AL7xxx segment accounted for a market revenue USD 22.0 Million during the year 2020 of the Aluminium Alloys in the Additive Manufacturing Market. This segment is expected to grow at a CAGR of 25.9% during the forecast period to reach USD 110.0 million by 2028. AL7XXX has been widely used in aircraft components manufacturing, it is one of the most important structural materials in the aviation industry.

Global Aluminium Alloy in Additive Manufacturing Market Revenue (USD Million), by AL7XXX, 2016-2028

The key factor that is anticipated to drive the market is the rapid development of the aviation industry and its modernizations. Moreover, a race for the development of lightweight UAVs for surveillance, owing to growing border threats among the countries across the globe is fuelling the market growth for AL7XXX in the additive manufacturing industry.

Powder Bed Fusion is the most adaptable manufacturing method in the development of Aluminium Alloy for Additive Manufacturing

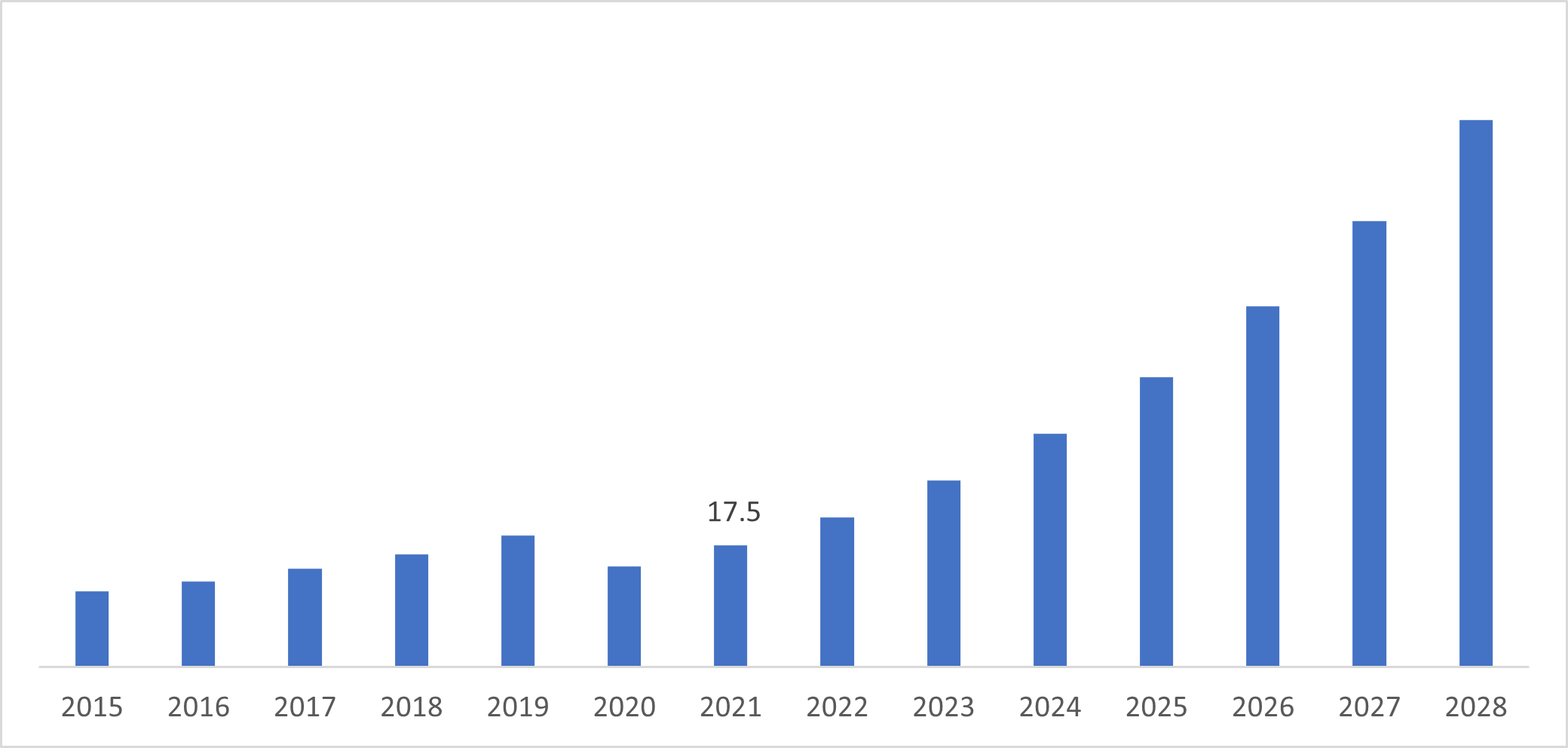

The powder bed fusion segment accounted for a market revenue of USD during the year 2020 of the Aluminium Alloys in the Additive Manufacturing Market. This segment is expected to grow at a CAGR of 24.1% during the forecast period to reach USD 198.3 million by 2028.

The Powdered bed fusion segment command the major share in the market owning to its quality and features induced to the components being manufactured such as high yield strength, ultimate strength, elongation, and hardness properties.

Global Aluminium Alloy in Additive Manufacturing Market Revenue (USD Million), by Powder Bed Fusion, 2016-2028

The U.S. dominates the market of Aluminium Alloy in Additive Manufacturing Market

North America is one of the leading regions with a high number of additive manufacturing products. Wherein, United States is the top revenue generating countries in this region.

U.S. Aluminium Alloy in Additive Manufacturing Market Revenue (USD Million), 2016-2028

The US has the largest installed base of 3D printers of 422,000 units in the world. Being a developed nation, the North American region is always in the race of implement and adoption of the latest technology just like 3D printing. Further, with the growing investment of the US towards new technologies in the field of aerospace for manufacturing of low weight high durable space crafts for space missions will drive the market of aluminium alloy in additive manufacturing.

Global Aluminium Alloy in Additive Manufacturing Market Competitive Landscape

Global Aluminium Alloy in Additive Manufacturing Market study is moderately competitive, with a considerable number of regional and global players. The primary strategies adopted by these firms include expansions, product innovations, and mergers and acquisitions.

Key Players

- EOS

- GE Additive

- AMC Powders

- Henan Yuanyang Powder Technology Co., LTD

- New Materials Development GmbH

- GKN Sinter Metals Engineering GmbH

- Metalysis

- Hoganas AB

An advanced distribution network gives a competitive edge to the principal market players in Global Aluminium Alloy in Additive Manufacturing Market. Furthermore, players need to innovate continuously, to work and grow in the market, due to the quickly evolving consumer needs and choices.

Recent Developments

- 2021 – Metalysis, announced that it has partnered with Australian Mines to obtain Scandium for aluminium-scandium (AlSc) alloy production and R&D. To capture the rising market of Aluminium alloy in additive manufacturing.

FAQ

How much is the Aluminium Alloy in Additive Manufacturing Market worth?

The Aluminium Alloy in Additive Manufacturing Market is worth USD 277.6 Million in 2028.

Who are the key players operating in this industry?

EOS, GE Additive, AMC Powders, Henan Yuanyang Powder Technology Co., LTD, New Materials Development GmbH are the major players operating in this industry.

Which region dominated growth of market during the forecast period?

North America is the largest share of the market growth.

Which is the main product segment in this market?

AL7XXX are anticipated to contribute the largest share to the product segment.

Table of Content

To check our Table of Contents, please mail us at: [email protected]

Research Methodology

The Market Research Community offers numerous solutions and its full addition in the research methods to be skilled at each step. We use wide-ranging resources to produce the best outcome for our customers. The achievement of a research development is completely reliant on the research methods implemented by the company. We always faithful to our clients to find opportunities by examining the global market and offering economic insights.Market Research Community are proud of our widespread coverage that encompasses the understanding of numerous major industry domains. Company offers consistency in our research report, we also offers on the part of the analysis of forecast across a range of coverage geographies and coverage. The research teams carry out primary and secondary research to carry out and design the data collection methods.